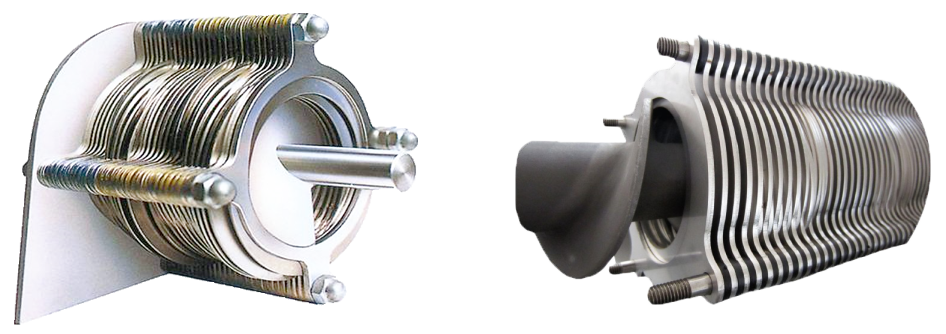

The Multi Screw Press(MSP) is used for dewatering applications especially for oily sludge. MSP integrates an automatic control cabinet, flocculation & conditioning tank, sludge concentration and dewatering zone and the filtrate collection tank.

Multi Screw Press(MSP)

APPLICATIONS

- Petrochemical Industries, Oil Refineries.

- Amyloid Industries, Pulp & Paper Industries.

- Blue Algae Dewatering, Municipal, Wastewater Treatment Plants, etc.

BENEFITS

- Can handle sludge with low to very high solid content.

- Sludge thickener is not required.

- Automatic & Continuous Operation with low energy requirements.

- Less space requirement & Closed equipment.

- Low maintenance as it has self-cleaning abilities which reduces clogging.

- Low operating cost and maintenance cost.

| Item | Belt Press | Screw Press |

|---|---|---|

| Advantages |

|

|

| Disadvantages |

|

|

| Moisture Content of Sludge Cakes | 85% | 80% – 85% |

| Polymer | ||

| Cleaning Water | Large amount for belt cleaning high pressured cleaning | Small amount for surface cleaning, spaying cleaning |

| Solids Recovery Rate | 80% – 95% | Over 95% |

| Power Consumption | Medium | Few |

| 24 Hrs Continuous Running | Difficult to achieve | |

| Sludge Thickener |