The Most efficient method to clean and restore aeration diffusers

- Aeration is the greatest energy consumer at a wastewater treatment facility amounting to an approximate of 45 to 70% of plant energy.

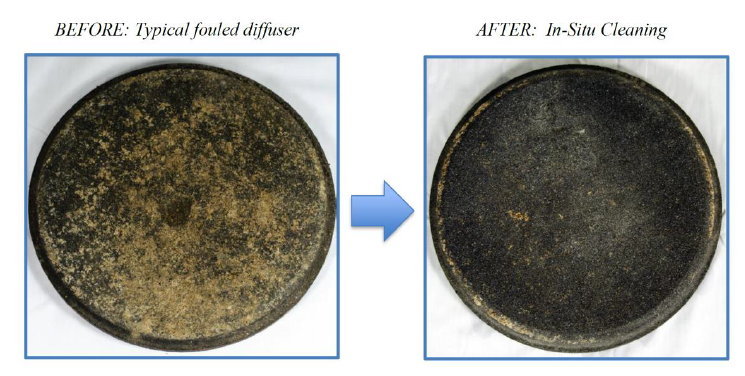

- All fine pore membranes foul regardless of make and manufacturer!!

- Factors that cause diffuser fouling: Bio Film coating, plugging diffuser orifice, scaling/precipitation of inorganic salts.

- Fouling reduces efficiency as well as performance.

Insitu Aeration Diffuser cleaning services

- Sureflo offers in-situ chemical cleaning of diffusers that not only clean the diffusers but gives better performance, efficiency and reduce energy requirements for diffuser operations.

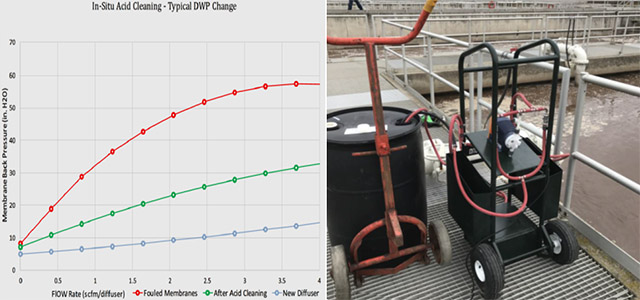

- Fouled State: Notice large bubbles and sporadic aeration pattern of a dirty membrane. – High Pressure & Low Efficiency.

- After cleaning: Bubbles are much smaller and more even distribution of air. Pressure and Efficiency Restored.

Insitu Aeration Diffuser cleaning services

ENERGY SAVING

- Significantly reduce energy that is devoted to running blowers for aeration.

- Reduction in energy = $$$ Savings $$$

- No need to take your system off-line. Can clean membranes while continuing to treat the wastewater and while the air is still on.

- Excellent alternative to the expensive option of replacing membranes. Consider cleaning before replacing membranes.

- Struggling to maintain DO – clean your membranes which will increase your oxygen transfer efficiency and increase DO.

- Blower pressure too high – clean your membranes which will reduce pressure and either turn down blower or turn a spare blower off.

- Local and knowledgeable support.

- Greatest return on investment.

- Extend the life of membranes by cleaning the membranes. All membranes are required to be cleaned periodically.

HOW DO YOU KNOW IF ACID CLEANING YOUR MEMBRANES IS RIGHT FOR YOU?

- Are you meeting Dissolved Oxygen demand?

- Are you using more air now (higher blower rpm, increased blower pressure, using an additional blower) to treat the same amount of wastewater?

- Are you looking for ways to cut costs and improve efficiency?

- Were you once able to get proper treatment, but now struggle to get required treatment?

- Are you meeting permit requirements?

Are your blowers popping the PRV valve (pressure relief valve) on occasion? - Is there an increase in influent that may require more aeration capacity?

- Looking for an economical way to clean your membranes (Ceramic or rubber)?

- Do you have funds in your maintenance budget but not capital budget to improve process performance?